FORD 1966 289 SPECIAL ENGINE REBUILD | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

THE G.T. 350 ENGINE The 1965 and 1966 Shelby G.T.350s were powered by a modified and slightly warmed over version of Ford's 289 Special "Hi-Po" engine rated at 306 HP @ 6000 RPM and 329 lb-ft @ 4200 RPM. Performance wise the difference was replacing the cast iron 4-barrel intake manifold with a COBRA lettered aluminum high rise intake and by using a 715 CFM Holley ceter-pivot carburetor in place of the standard Autolite 4100 595 CFM unit. The exhaust received a set of tubular "Tri-Y" headers. Part way through the 1966 model year, the carburetor was switched back to the Autolite 4100 on automatic cars, as it ran better than the Holley with C4 transmissions. To create a unique appearance for the engine, COBRA lettered rocker arm covers were added as was a finned aluminum COBRA lettered oil pan. The same basic engine was used for 1967, however, the Tri-Y headers and aluminum COBRA oil pan were left off in a cost savings move. BACKGROUND ON SFM6S817's ENGINE At some point in this car's deep dark past, the original engine was removed for unknown reasons. A 1968 302 2-barrel engine was substituted in its place. This engine had been fitted with a dual point distributor and what was supposed to be the stock solid lifter 289 Hi-Po camshaft. When my dad bought 6S817, the original short block was part of the deal. The engine had been sitting outside in the weather since before the owner had bought it. The block was rusty and the rotating assembly didn't - ah, rotate that is. The pistons on one side of this block were well and truly seized. My friend Mark and I had to break up those four pistons to take the short block apart. What we were left with was the block itself, the crank shaft, and the connecting rods. We did take a wire brush to the passenger side of the block and found a VIN stamped into it. It turned out that the number on the block was a match for the Ford VIN under the right side fender (the left side had been in a collision at some point in the past and the inner fender apron had been replaced, so there was no Ford VIN in that location). Years later I sent a picture of the block VIN to Howard Pardee, the SAAC 1965/1966 registrar. He confirmed that the Ford VIN still was a match to their records. I've always wanted to return the original engine to the car it belonged in. But I realized that it would be quite the task to undertake a rebuild as I wouldn't have that much to work with and so the bare block sat for many years untouched. Fast forward four decades. I had inherited 6S817 and the block was sitting in my garage next to the G.T.350 beneath some metal shelving. I was regularly going to local and national car shows with 6S817. Even though the car had not been restored it still drew complements mostly because of its semi-unrestored state. People seemed to like the car's 50 year old patina. Over the years though, I had made small changes under the hood. I had replaced most of the bolts with Allen head bolts, the ignition wires were not stock, and the water and fuel pumps were plain service replacements. I had to tell spectators that they were not looking at the original engine, it was a '68 302 but it did have a Hi-Po cam and a factory dual point distributor. I finally got to the point were I decided that enough was enough, the 289 had to get rebuilt to mostly stock specs and find its way back into the car. Eventually I was offered an Autolite Hi-Po 289 carburetor which I bought for what at the time I considered to be an exorbitant amount of money, $1,300. I'm glad I bought it because shorty after my purchase they more than doubled in value. I also invested in a look alike fuel pump (original remanufactured Carter 4201S pumps costing around $2,500), a Ford remanufactered unit at $400 and a rebuilt 289 Hi-Po water pump at $400. I found an early Autolite alternator with the correct case for $15 at the 2017 All Ford Nationals in Carlisle and spent another $65 getting it rebuilt at a very good local generator and starter shop. In the course of researching the alternator I found out that there are three distinct styles to choose from: 1965-1966, 1967-1968, and 1969-1970. The '65-66 cases being the scarcest of these. The engine was already equipped with a number of correct Shelby unique parts: "open" COBRA lettered rocker covers which are original to the car, cast aluminum finned COBRA lettered oil pan which was bought shortly after the car was purchased, correct COBRA lettered S2MS-9424-A intake manifold, and correct Hi-Po 289 fan and fan shroud. The oil pan came from Florida via a Shelby club advertisement, the intake was located courtesy of a local automotive classified, the fan shroud was purchased straight over the Keats Ford's parts counter (the parts manager warned me when I went to pick it up "you know that this thing is metal not plastic"), and I found the fan at a swap meet for something like $25. In order to complete the picture of a vehicle that had stepped right out of 1966, I obviously needed to rebuild the original engine. The big question was which heads to use as we hadn't gotten any with the original short block. I basically had three choices: 1) use the heads that were presently on the car which I assumed were '68 302 heads with aftermarket screw-in-studs and pushrod guide plates, 2) use a different set of '68 302 2V heads that I had laying around and convert them to high performance specs, or 3) locate another set of heads and use them. After much reflection on the matter, there really was only one choice to be made, find a set of Hi-Po 289 cylinder heads. The head search started in earnest at the 2018 All Ford Nationals in Carlisle, PA and casually looking on Ebay. After about a year of looking, I found a set at the 2019 All For Nationals on Saturday. They were being offered for sale by one Wayne Zastrow, who was from a small town in the middle of Wisconsin. Wayne is a fellow '67 G.T.500 owner and was selling the heads for a friend and while the price was pretty salty for my taste, they were about in line of what I'd come to expect to pay for these rarities. Like everything Hi-Po unique, these things had steadily risen in price over the last decade or so. I had, in my ignorance, told Wayne I was looking for a set of '66 heads. He asked "are you sure?" Well of course I was sure, I had a '66 car so it must need '66 heads, right? Not so fast grasshopper. It all depended on the block casting date which Wayne asked me about. I had to admit that I didn't know but I would find out when I got home and I would call him with the information. I told him I wasn't planning on coming back on Sunday and if we made a deal we'd have to do it over the phone. The heads he had with him were date coded 5H23 (August 23, 1965) and 5H26 (August 26, 1965). When I got home, I took a quick look at the block and discovered that the casting was dated 5K23 (October 5, 1965). Sunday I pulled the G.T.350 out of the garage to get a better look and to take some pictures. While closely examining the block I also found the engine assembly date code 5L3 T. That decoded as November 3, 1965. The "T" was the assembler's initial. I made inquiries on the SAAC Forum and found out that while the heads were dated a bit early with respect to the block, they were still within the realm of possibility. That was good enough for me as I'm not a real stickler for dated parts. Over the next couple of days I struck a deal with Wayne to purchase the heads. Now you might think that I would have a problem since the heads had gone back to Wisconsin. Not really. In one of the coincidences that sometimes happen in the universe, Wayne told me that he knew a great machinist who was local to him that he took all his engine work to. This machinist worked alone, was honest, was nothing short of a perfectionist, and was affordable. Sounded like my kind of guy. So I gave the go ahead for Wayne to take the heads up to Custom Precision Services run by Dan Hoefler, a one man operation. Dan does all the engine work for a nationally known restoration shop in Green Bay that specializes Shelby cars and parts. Once Dan had had a chance to look the heads over he gave me a fixed firm price which I agreed to. The coincidence I mentioned before? I go out to Oshkosh for the EAA Airventure show each year and 2019 would be no different. Dan's shop happened to be about a half hour from the show. We agreed that I would pick up the heads while I was in Oshkosh. I asked Dan to take pictures of the work as it was being done which he agreed to. However, he had already tumbled the heads to remove all the rust so there would be no "before" pictures. The pictures arrived via email and looked great. I asked Dan if he would take a look at the block if I brought it to him when I came by to pick up the heads. This he also agreed to. My daily driver is a 2016 Ford Focus. For the trip out I devised a method to strap the block down and loaded it up in the back. And off we went. After setting up camp at the AirVenture event, I headed down to Wayne's house and then back up to Kaukauna where Dan's shop was located. To say that I was blown away by all the equipment in the shop would be an understatement. It certainly was one of the cleanest shops I've ever seen with everything meticulously put away and organized. Dan showed me the heads and then gave me a tour of the shop before heading out for lunch. When we got back we had a more detailed discussion of what it took to restore the heads and a better description of the shop equipment as well as the method and techniques Dan employed in his work. I was thoroughly impressed by his professionalism. Dan devoted about half of his day to me and answered every question I had. And I had a lot. We finally got around to the topic of the block which we unloaded from the car. Dan said that he had seen worse but wouldn't know how much the cylinders would have to be overbored to clean them up until he actually did the work and sonic tested the walls to see how much metal was available to work with. That was not unexpected. I told him that I didn't want to go more than about 0.010" or 0.015" oversize and anything more than that might need to be sleeved as I'm not a believer in immediately going right to 0.030" over. We also talked briefly regarding the crank gear, the special counterweight, the timing chain, and cam gear, all of which are unique to the 289 Special. The question was should I go completely stock or use a standard performance aftermarket gear? The stock crank gear is a bit thinner (by 0.150") to accommodate the special counter weight that was designed to dampen 4th order vibrations on the crank that was the result of the increased weight of the connecting rods. I'll have to think about that one. The final decision deals with the camshaft, do I use an exact Hi-Po duplicate or a modern equivalent? There are about three choices here. Howards Cams and Comp Cams make an almost exact replacement cam for the 289 Special. Comp Cams also makes a "Nostalgia +" cam that is one step up from the stock solid lifter. I'll probably choose the exact replacement by Howards Cams. The Covid-19 pandemic caused a cancelation of the 2020 Oshkosh AirVenture event and prevented any chance to go back out to Wisconsin. So I concentrated on deciding which cam to use and collecting parts for the engine. After much thought and consultation with Dan Hoefler, I selected a Howards Cams reproduction Hi Performance grind (CL217322-14). From my research, this profile is the closest one out there to the stock camshaft. (I have since learned that Homan Moody also makes an exact replacement cam.) I tried to contact Dan regarding the plans for the block from 2020 through 2022 but got no response. We finally went back to the airshow in 2022. I had $1,000 in cash in my pocket to get things started with Dan. I phoned him from the show grounds and asked if we could meet to discuss the engine. I was quite surprised when he told me that he was too busy to take on my engine and that I should just stop by and pick up the pieces. I'm not sure what I did, if anything, to sour the relationship. Anyway we loaded up the car with all the parts I had supplied him and took them back home to Pennsylvania. The day after we got back home, I took the parts to a local machine shop that had been recommended to me. Doug Meyers has a very good reputation in the area and is a Ford guy as well. We agreed that he was going to do a long block for me and also degree in the cam. So now I'm waiting for notification that the the job is ready for pick up. One thing he said was that we wouldn't be able to use was the crank. As mentioned before, it had suffered extensive rust damage from Hurricane Floyd back in 1999. A chance encounter at Doug Meyers' shop put me in contact with someone who had a Hi-Po crank. I was thinking if this crank checks out, I'll just use that one. Click the links below to view picures of the machine work performed on the block and heads.

THE STARTING POINT – Original and Used Parts CRANKSHAFT

The crank was in pretty poor condition thanks to a flooded basement courtesy of Hurricane Floyd in September of 1999 and was not used. Instead a good used crank was obtained from Dan Keiefer. This crank was eventually cut .010 / .010.

CONNECTING RODS

The connecting rods are genuine 289 Hi-Po from the original engine. Fortunately, they did not suffer the same fate as the crank.

HARMONIC BALANCER

The harmonic balancer was found at a swap meet at Raceway Park in Englishtown, New Jersey many years ago. I think I paid around $15 or $25 for it. It looks like the hub will be needing a sleeve in order to put it back in service. The balancer is dated January 1966 (A6), actually just a bit too late to have been used in the original build of this engine by Ford.

HARMONIC BALANCER BOLT & WASHER

WATER PUMP

The water pump was bought off Ebay. It is a rebuild Hi-Po 289 unit with the correct 6-vane impellar.

FUEL PUMP

The fuel pump was also bought off Ebay. It is not a true Carter 4201S Hi-Po 289 unit but is a Carter 3909S. The only real difference is the 3909S pump is lacking an additional spring to help keep the pump arm in contact with the cam eccentric at high revs. As long as I don't twist this engine above 6000 RPM or so, it should be fine.

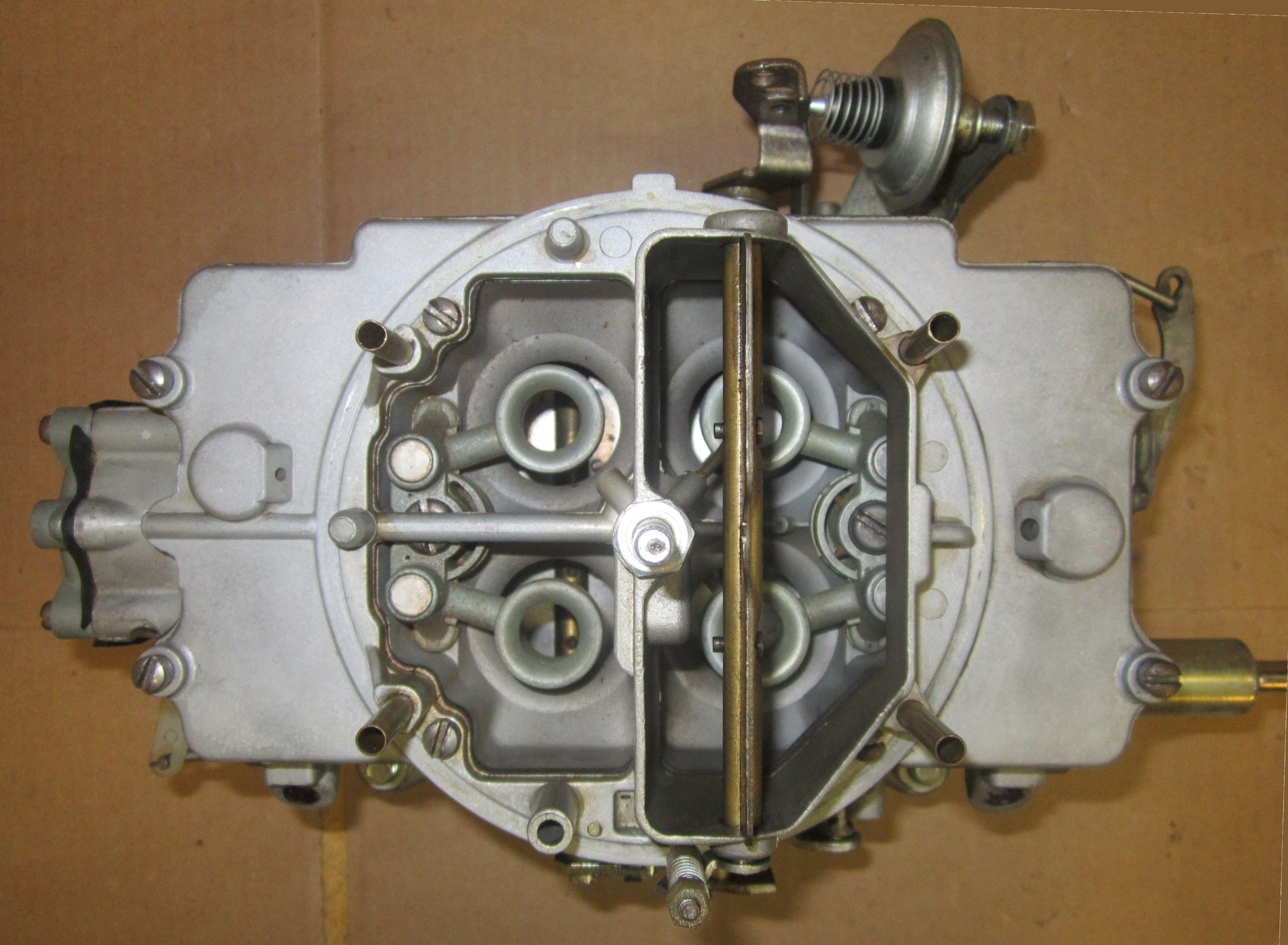

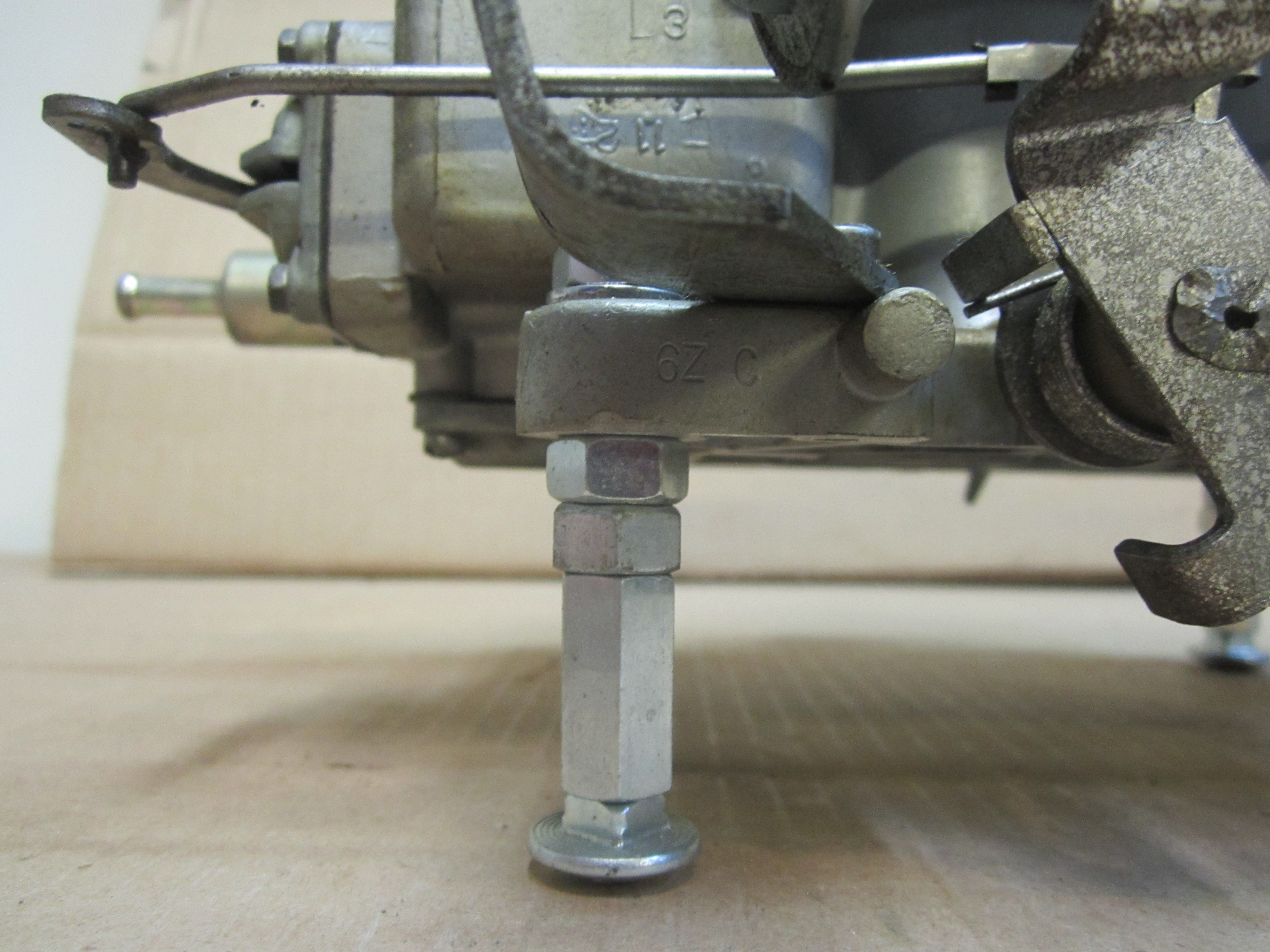

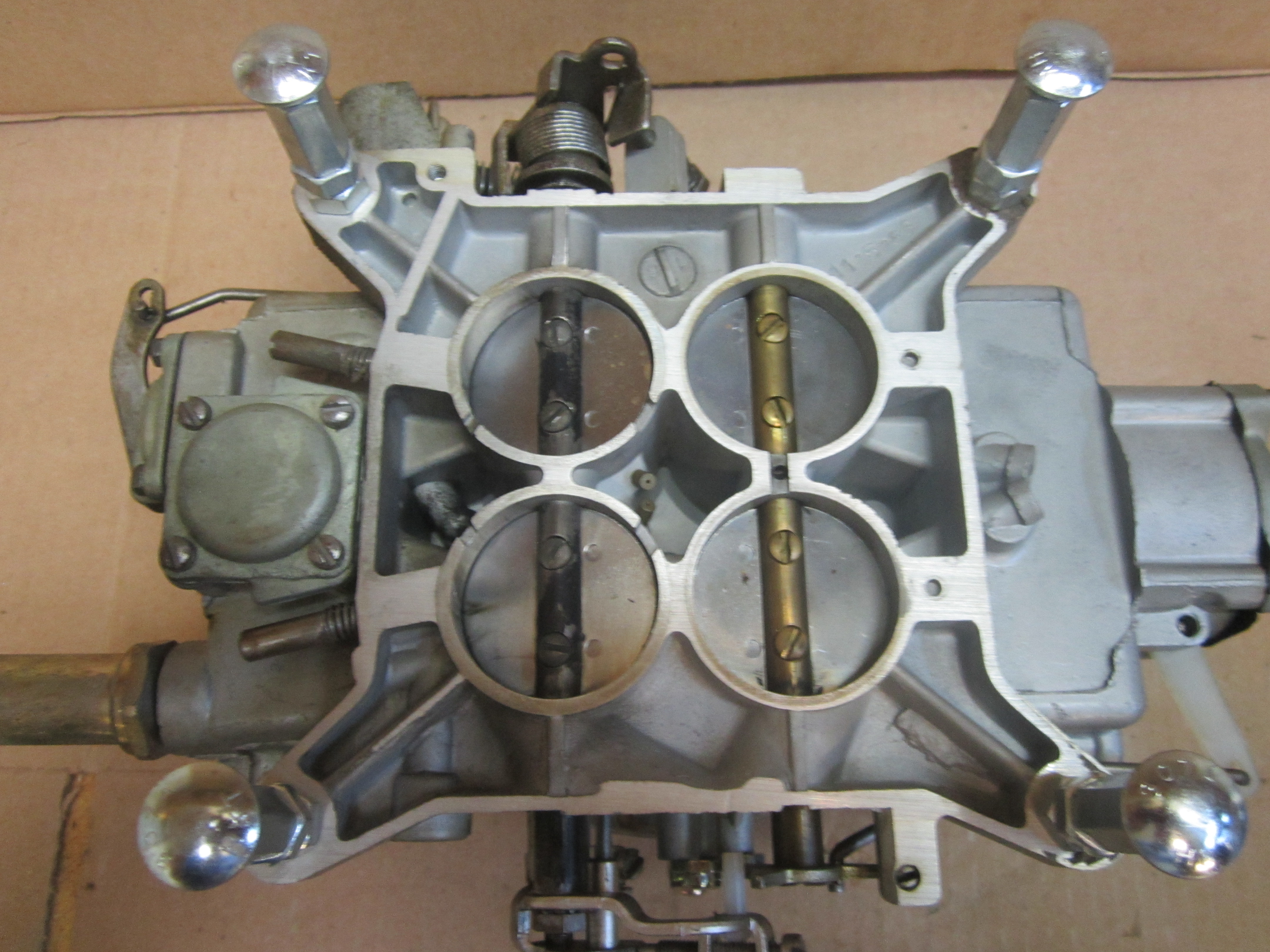

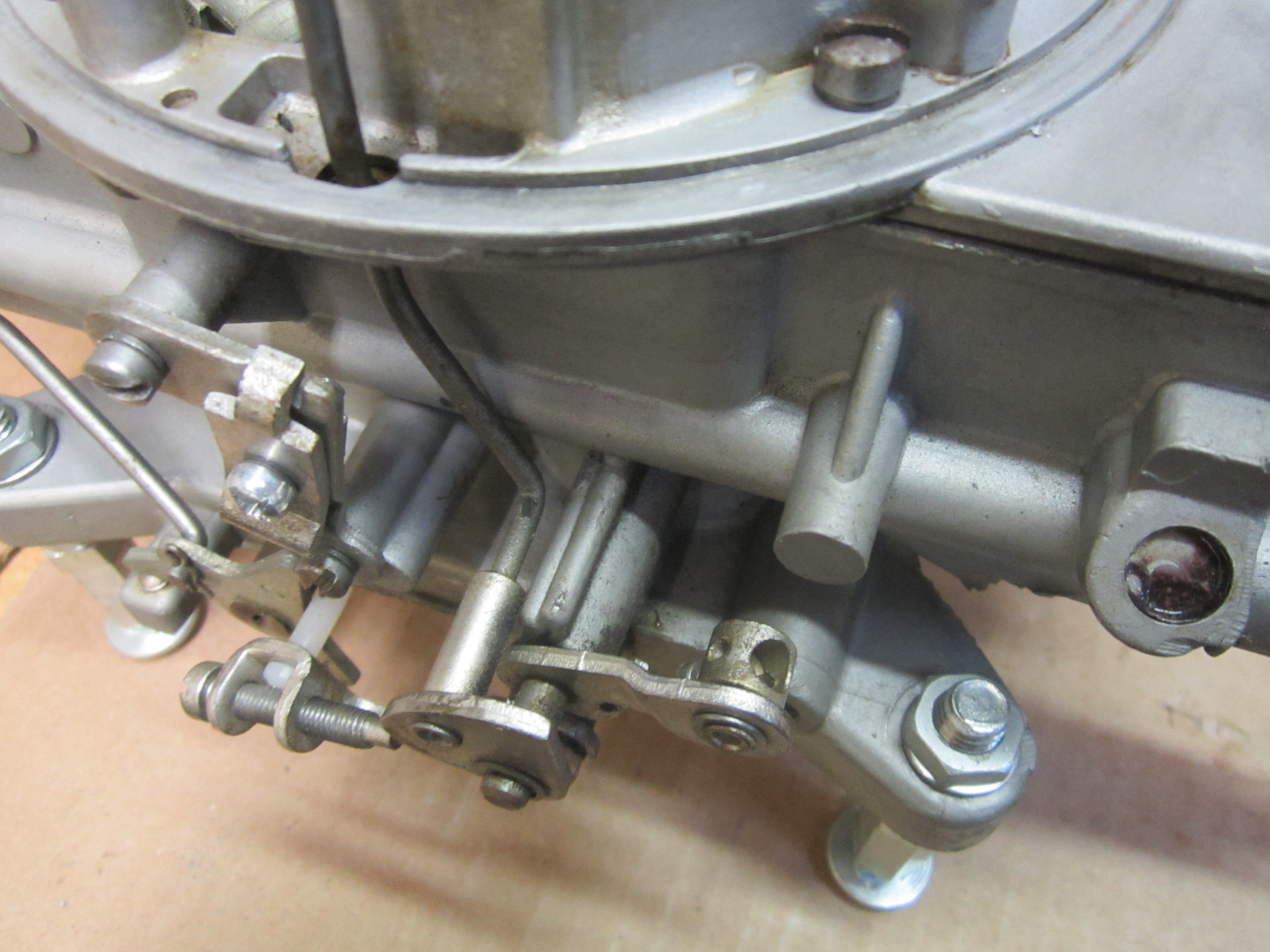

CARBURETOR

The Carburetor was bought from a fellow Hertz car owner. It is a true Hi-Po 289 carburetor although it is for a 4-speed transmission (C6FZ-C) car instead of an automatic transmission (C6ZF-F) car. The only differences between the two that I'm aware of is the addition of a dashpot for the automatic transmission and the primary booster venturi having a slightly different calibration (marked MA vs. M). Even today, experts consider this carburator to be state of the art featuring annular discharge nozzles and emmultion tubes in the booster venturis.

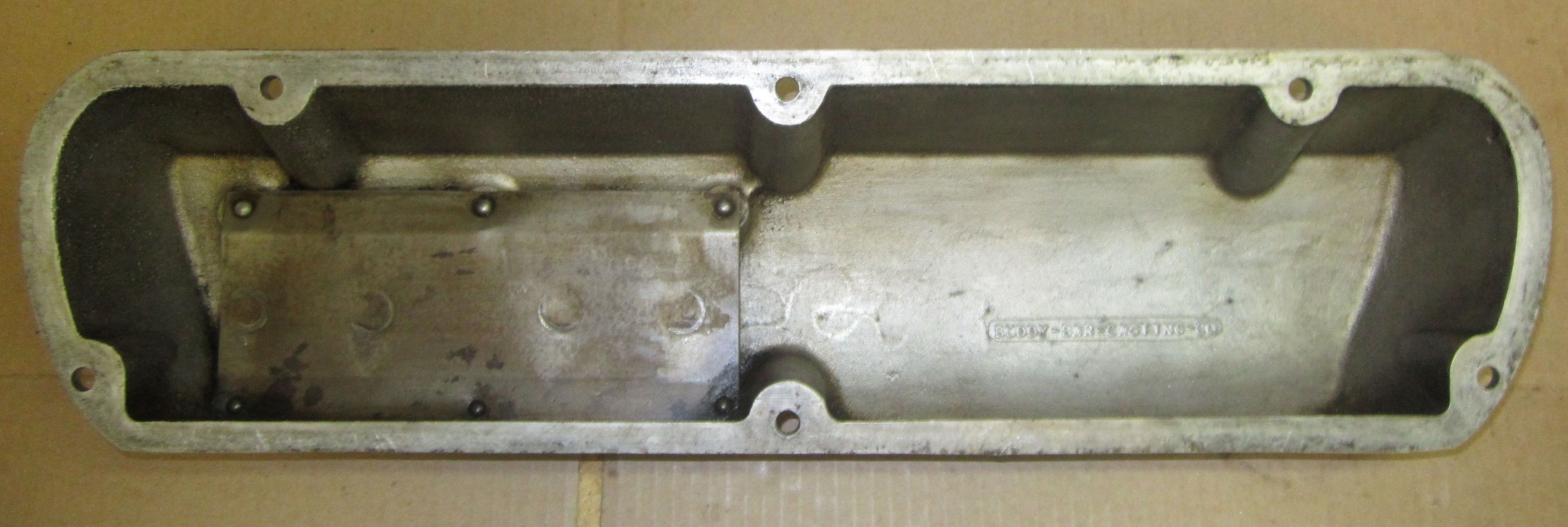

ROCKER COVERS

The rocker covers are original Shelby American parts and were on the car when purchased. They are a sand casting by the Buddy Bar Casting Company who was well known for casting finned aluminum oil pans, intake manfolds, and other assorted parts. These rocker covers carry COBRA and POWERED BY FORD lettering and are known as "open letter". Marks on the underside of the oil baffles come from using polylocks on the rocker arm studs. Polylocks have always been a problem with this style rocker cover due to interference between the top of the lock and the cover. The polylocks were added by a previous owner and were on the engine when purchased. The use of the standard rocker stud locknut on the rebuilt heads will prevent further damage.

OIL PAN

The finned aluminum oil pan is another Buddy Bar Casting Company product. Aside from the fact that it looks pretty cool and has COBRA lettering on the side, the fins help dissipate heat. It has a two quart larger capacity than the stock 289 pan and is internally baffled to direct oil towards the pickup during hard cornering. One drawback is that the pan is quite heavy. This pan was bought out of Florida shortly after the car was purchased.

OIL PUMP

The oil pump is a standard volumn replacement pump. The high volume pump costs HP to turn the longer gears and doesn't put more oil into the engine due to the diameter of the oil passage into the block. Even the factory built T/A engines used a standard volume pump to supply the engine. OIL PUMP BOLTS

Oil PUMP PICK-UP

The oil pump pick-up is a standard replacement part. OIL PUMP PICKUP BOLTS

OIL PUMP DRIVE

The oil pump drive is a heavy duty piece that is considerably beefier through the middle of the shaft and suitable for racing engines. The shaft is produced by ARP for Ford Performance. CAMSHAFT

The Howard's CL217322-14 camshaft is advertized as a near duplicate of Ford's C3OZ 6250-C 289 Special solid lifter camshaft and is part of their "American Muscle" series that tries to match factory performance cams and should do nicely in replicating the performance characteristics of the 289 High Performance engine. The camshaft plays a major part in determining the chacacter of the engine.

LIFTERS

Howards offers a "DL" version of the lifter which meters oil directly from the lifter through a small hole in the bottom of the lifter and onto the cam lobe. Increasing oil supply to the lobes is critical. A precision "E.D.M." laser burns a .021" hole in the center of the face of the lifter. This allows a constant oil supply to the cam lobe, allowing higher valve spring pressures, more aggressive profiles and reduced lobe wear.

CAMSHAFT THRUST PLATE

The Camshaft Thrust Plate is a standard 0.250 inch thickness piece manufactured by Melling. CAMSHAFT THRUST PLATE BOLTS

The Camshaft Thrust Plate Bolts were sourced from AMK.

ECCENTRIC - CAMSHAFT FUEL PUMP DRIVE

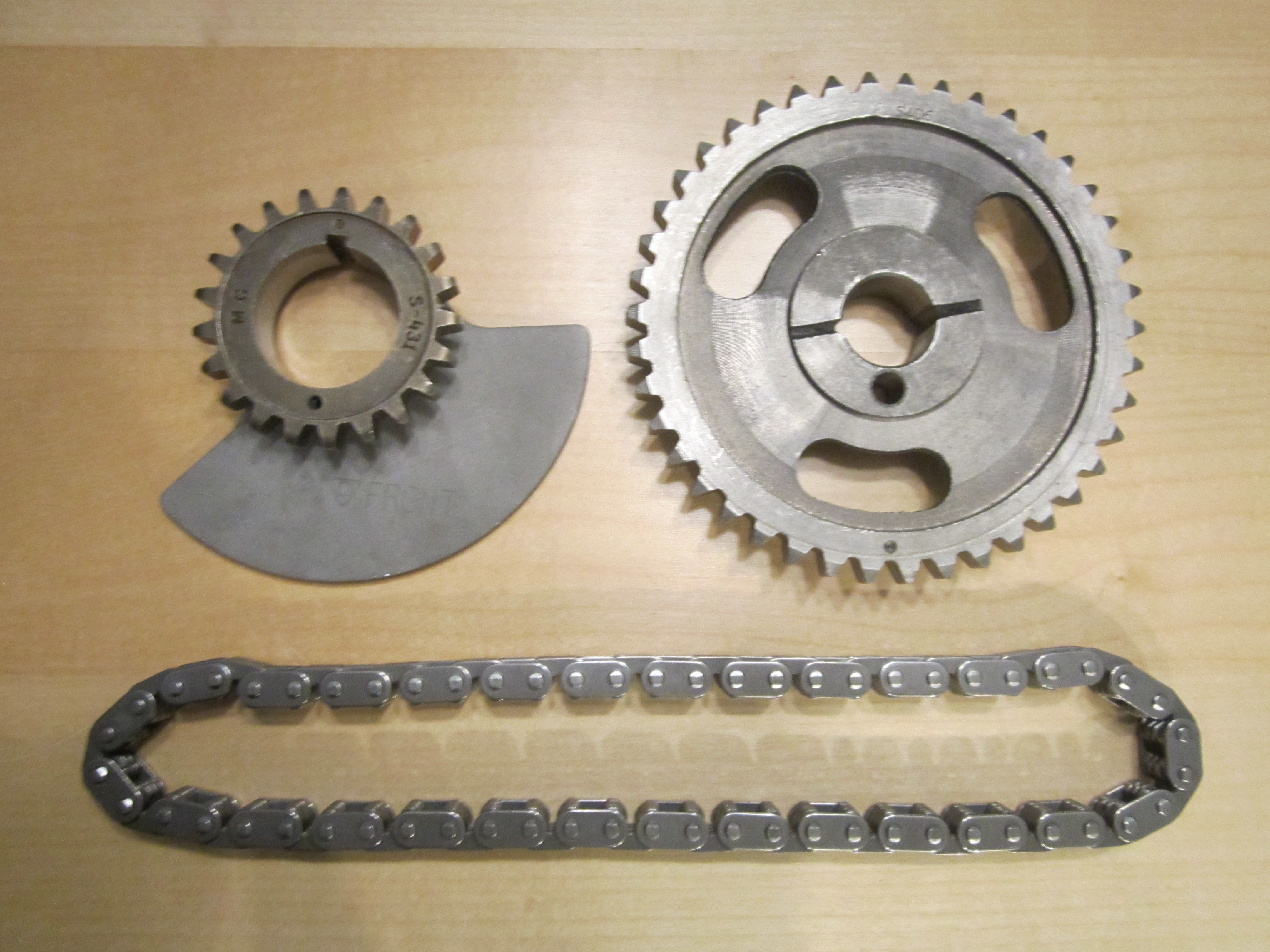

This part is not widely available as a replacement of the same design other than through Ford Performance. TIMING GEAR SET

The pictured timing set looks stock but the crank gear has in fact been machined down by 0.150 inch on the back side to accommodate the special 289 Hi-Po counterweight. The use of a standard crank gear without removing enough material to compensate for the counterweight thickness would cause misallignment between the crank and cam gears. To prevent 4th-order harmonic vibrations from destroying the crankshaft at higher RPM, the engine used a different vibration damper and an add-on counterweight. A portion of the 28.2 oz-inch imbalance found in the normal small block damper was moved to the additional counterweight. Moving the mass in towards the front main bearing reduced bending loads on the crankshaft. The special damper also had a larger more massive inertial ring. The add-on counterweight was 0.150" thick. As a result a special crank sprocket was used (C3OZ-6306-A), itself being 0.150" thinner than the normal 289 sprocket (C5OZ 6306-A). The counterweight was both keyed to the crankshaft and indexed to the sprocket with a 1/8" roll pin.1

HEAD BOLTS

Head bolts for the 289 come in two sizes, the shorter ones are for the lower side of the engine while the longer bolts service the upper portion.

WOODRUFF KEY

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg)

_1.jpg)

_2.jpg)

_3.jpg)

_1.jpg)

_2.jpg)

_3.jpg)

_4.jpg)

_5.jpg)

_6.jpg)