THE MICO MASTER CYLINDER | |

One of the unique and least understood features of the Hertz Car is the use of the Minnesota Automotive Company (or MICO for short) "piggyback" master cylinder. The installation of the MICO master cylinder was an attempt by Shelby American to alleviate reported problems with the brake system on the Hertz rental G.T.350s as being ineffective. It turned out that most customers were not familiar with what was essentially a race car brake system where the brake pads needed to heat up before they were effective and would stop the car. Many renters would interpret this as the brakes not working properly. And so the MICO master cylinder was tried as a pseudo power brake solution to provide more force to the brake pads in an effort to give a more positive feel to the brakes and stop the car which gave an odd feel to the brake pedal. The system used an internal piston-within-a-piston setup to provide the extra force. Ultimately, this approach proved unsatisfactory and the braking system reverted to the stock Mustang disc brake pads and brake shoes and the elimination of the strange MICO master cylinder which solved the problem to Hertz's satisfaction.

| |

| |

Hertz Cars had this lable applied to either the dash, as shown here, or just below the radio. Purpose was to warn drivers that these brakes were different.

| |

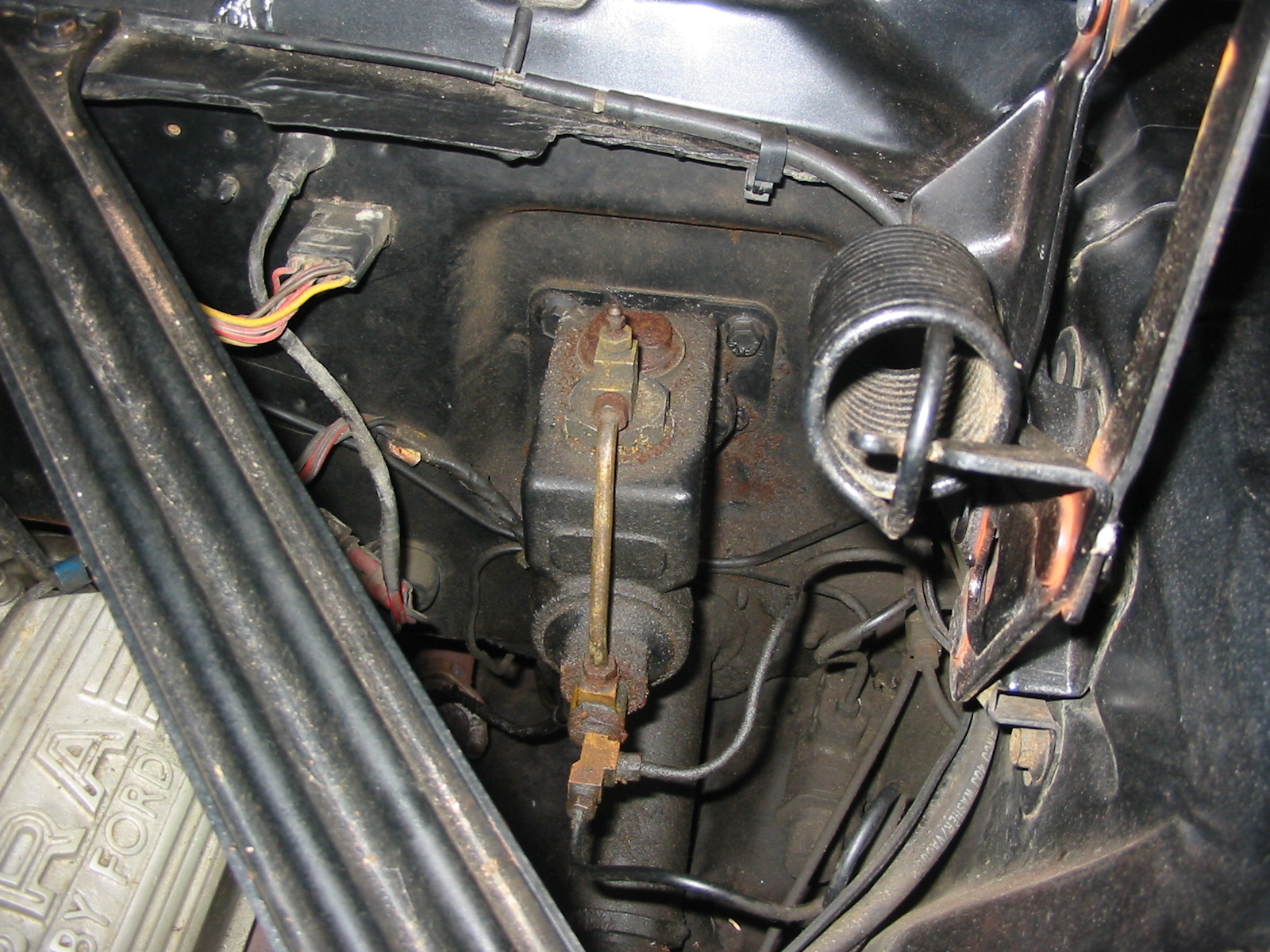

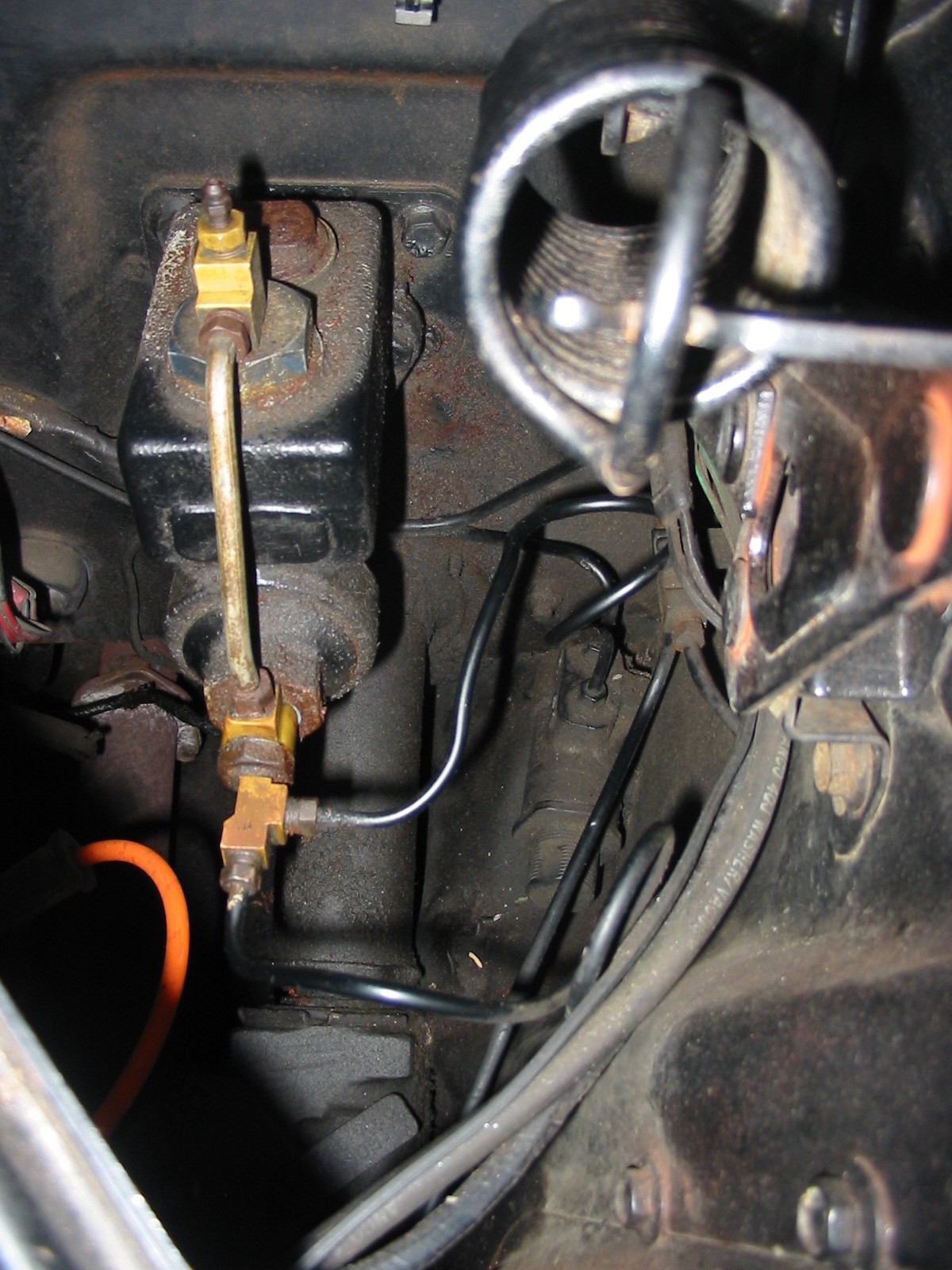

These are pictures of a MICO master cylinder as installed in a Hertz Shelby American G.T.350, in this case SFM6S817. Note that the brake line distributon block and proportioning valve are the same as any front disc brake equiped Mustang.

| |

|

|

Top ¼ view. Master cylinder is filled from rear port. | Sideview showing lettering cast into master cylinder body. Front port is anodized aluminum and mounts the master cylined bleeder. |

|

|

Right front ¼ view. | Part number 704B1 is faintly visible on front of casting. |

|

|

Distribution block and proportioning valve are visible in this picture. | The uniqueness of this system is really shown off in this shot. |

|

|

The fitting and bleeder valve that sit on top of the front port. Thread is ⅛ NPT. | The bleeder valve. Thread is ¼-28 |

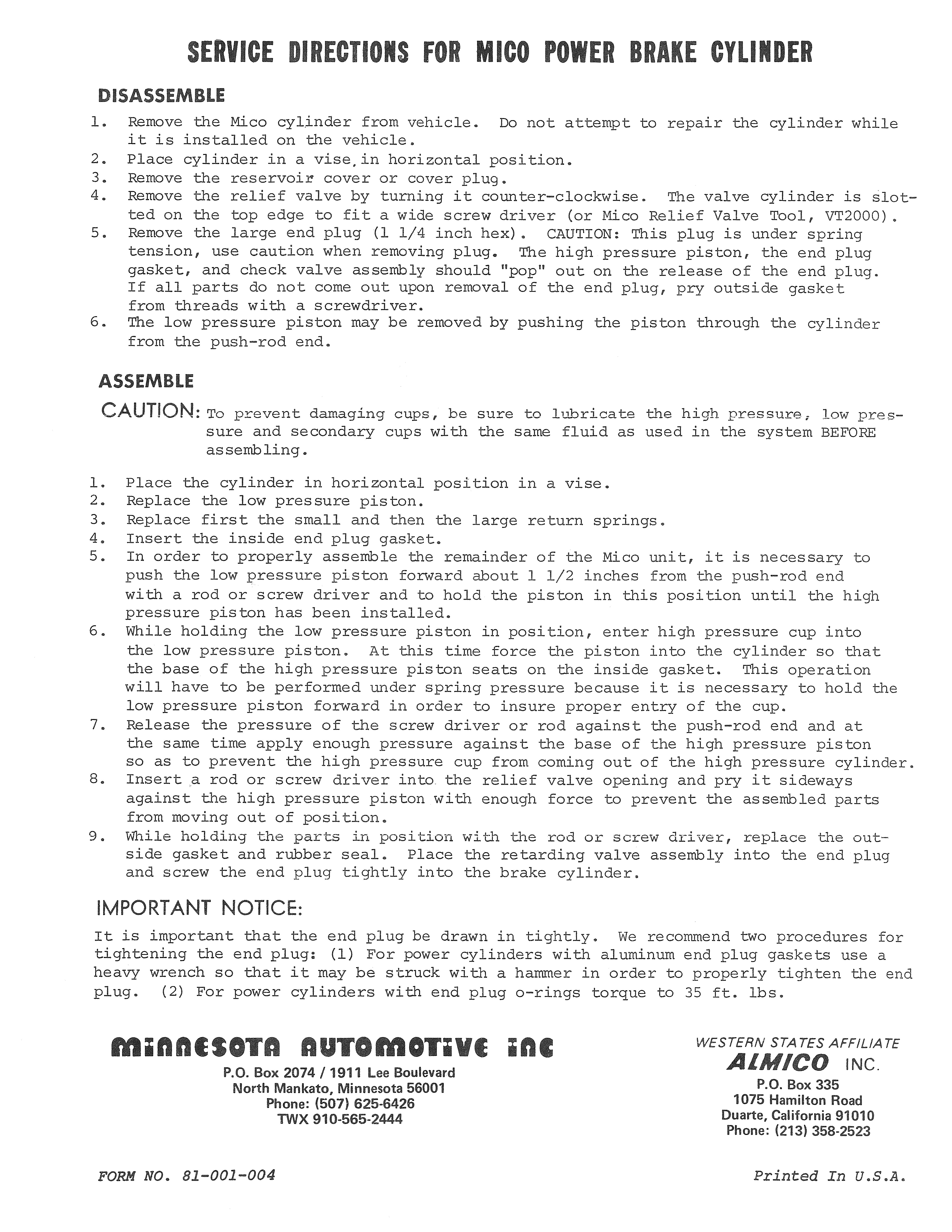

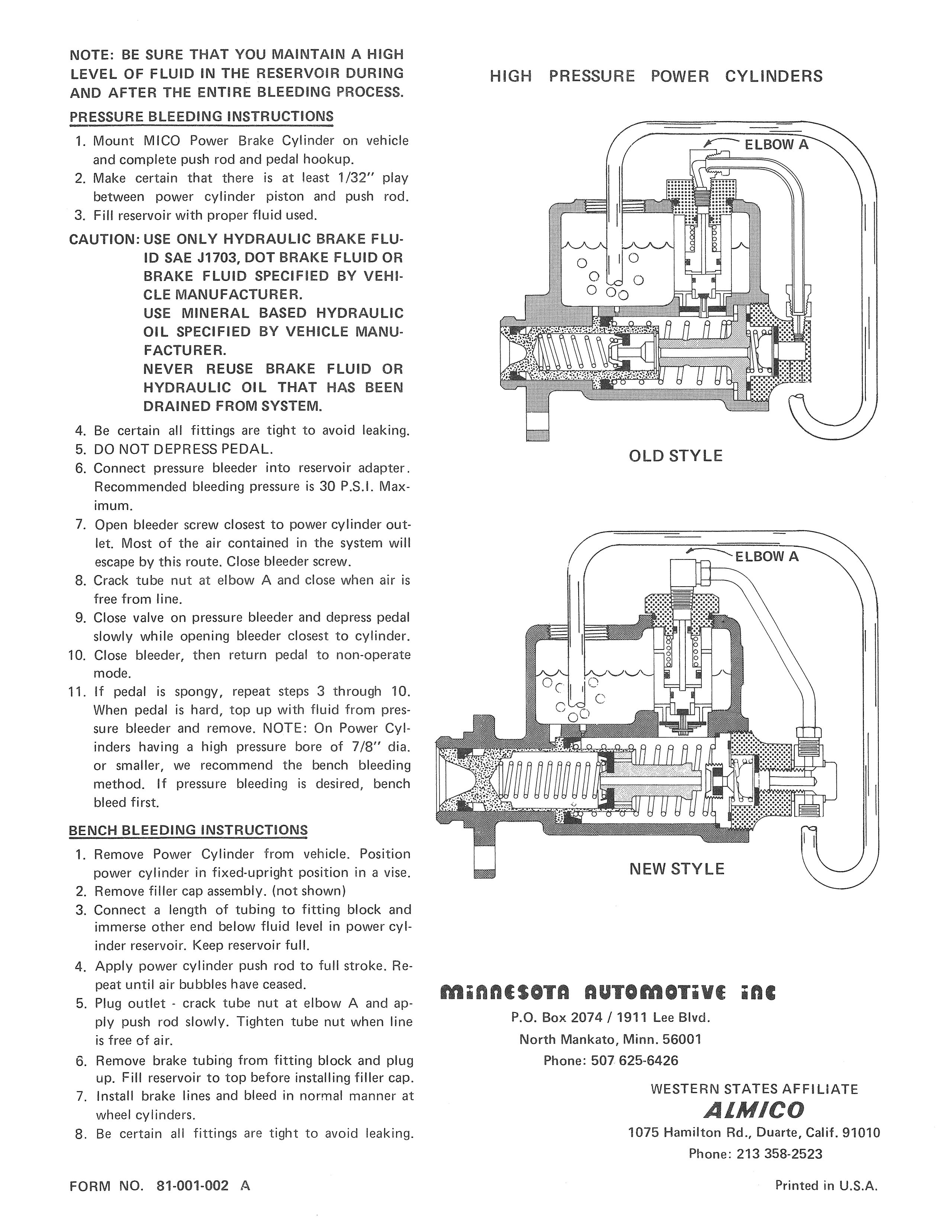

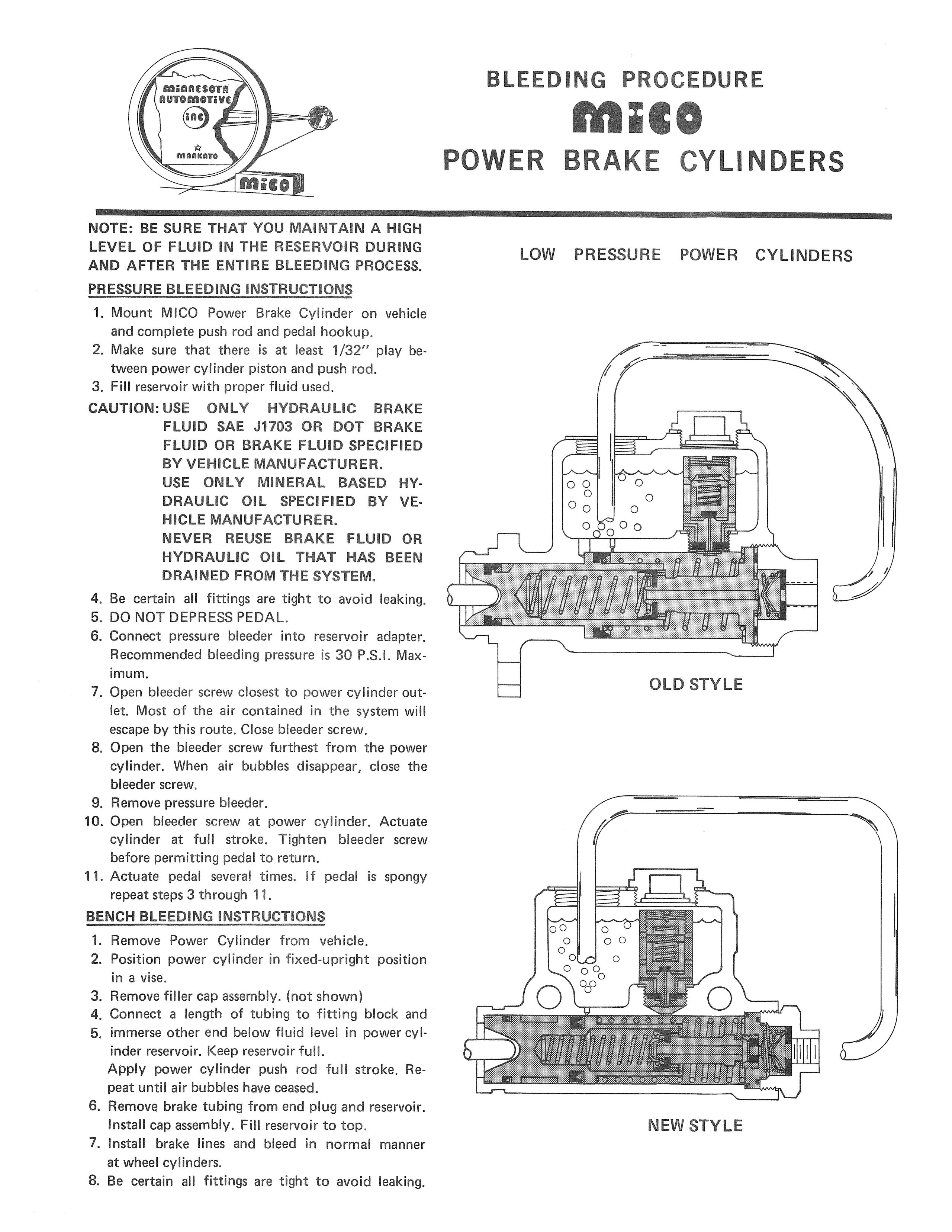

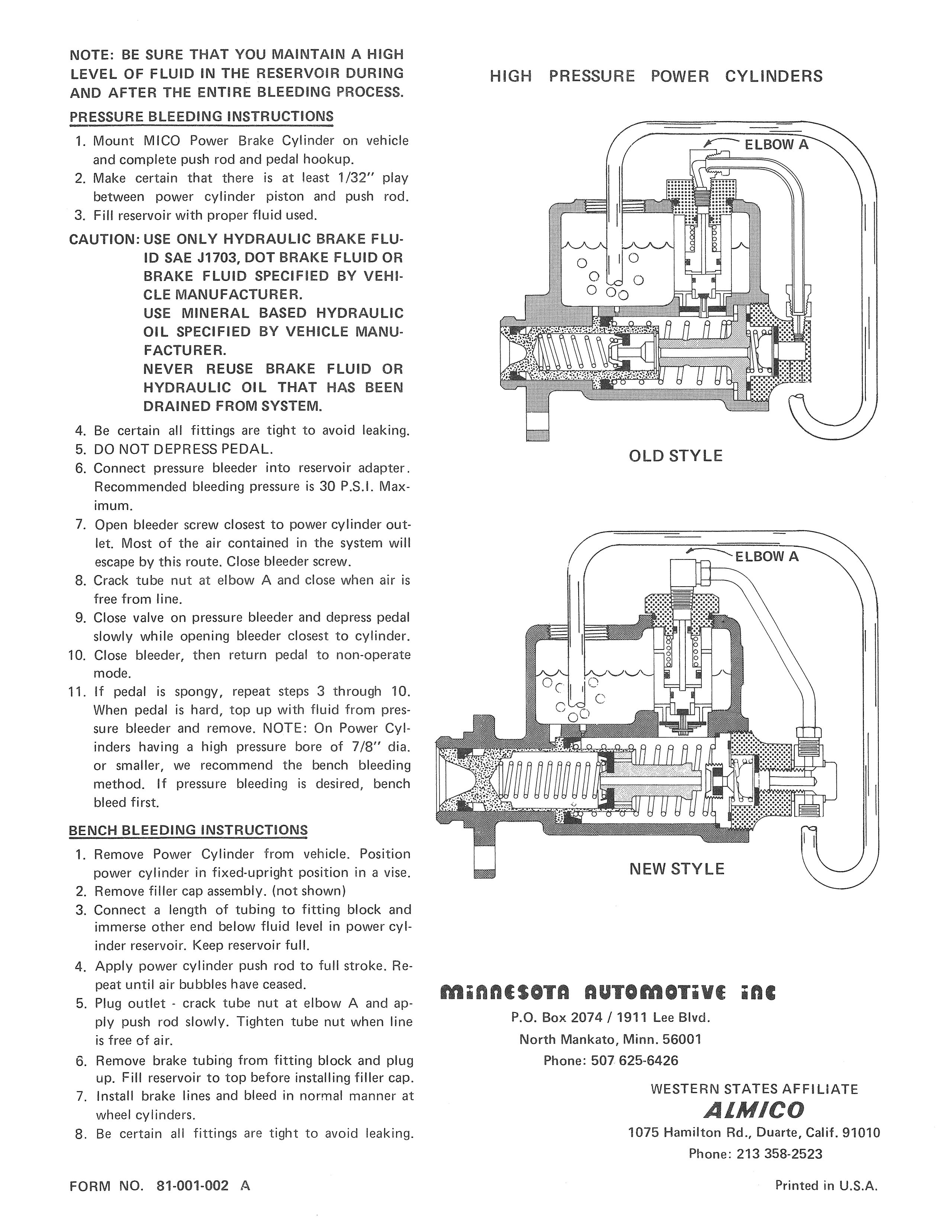

Presented here are copies of the servicing and bleeding instructions I received when I ordered a rebuild kit for the master cylinder on SFM6S817 some forty years ago as I write this. | |||||||

SERVICING PROCEDURES

|

|

| BLEEDING PROCEDURES

|

|  | |

| Web page created by S-Tech Enterprises, LLC. Last revised: July 11, 2020 |